Design

Publish

Deploy in seconds. Your site is fast out of the box and automatically optimized for search engines.

01

02

Scale

Scale your site to any size with the built-in CMS, AI-powered localization, and site maintenance tools.

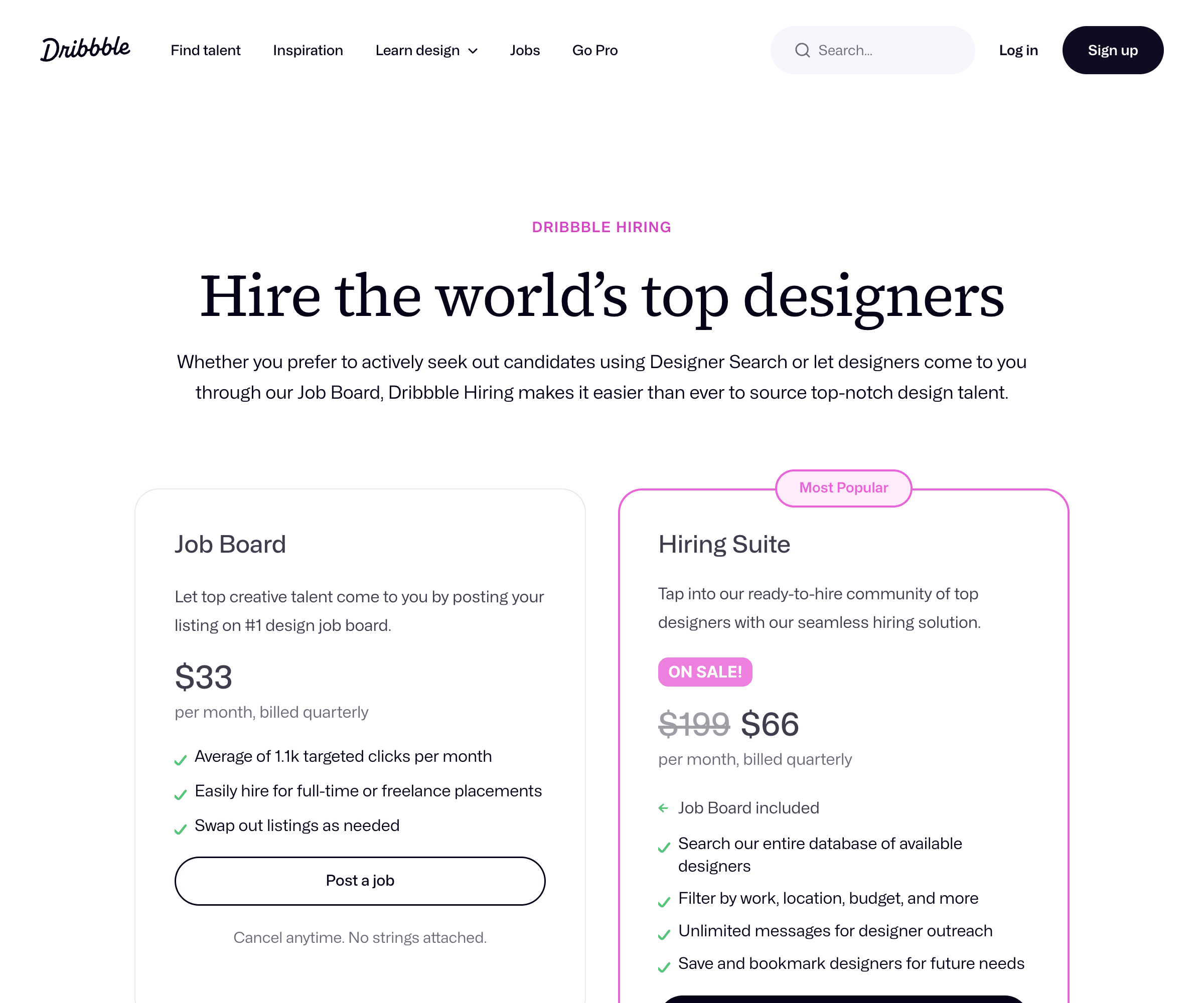

Built-in CMS

Title

Date

Tint

Image

Exploring Parallax Scrolling in Web Design

5 January 2023

How to Become a Better Web Designer

10 February 2023

How to Create a Website

18 January 2023

Building a Responsive Navigation

28 December 2022

How to Make Accessible...

16 December 2022